This incident helped to outline sterility assurance in an operational way. Processes and necessities for products validation have been established, and lawful suitable of inspection was explicitly presented for the company.

Part four: Draws interest to how very important senior management is to verify the PQS has successful document Management and administration strategies.

Documents should have unambiguous contents. The title, nature, and reason needs to be Obviously said. They have to be laid out within an orderly vogue and become simple to examine. Reproduced documents has to be apparent and legible.

In the event of hand penned document like ROA, if a lot of the details are exact like reagent preparation or chemical aspects. can it be permitted to fill it in a single doc and the other document has its reference no. only?

Created strategies must be founded and adopted for the review and acceptance of batch production and laboratory Regulate information, like packaging and labeling, to determine compliance from the intermediate or API with recognized specs right before a batch is introduced or distributed.

Right here at JAF Consulting, Inc., we fully grasp the complexities and challenges that come with preserving GDP compliance. We intention that can help businesses navigate these prerequisites, empowering them to accomplish the very best benchmarks of information integrity and quality management.

, are usually not essential, delivered the batch file has total traceability of the facts. In case of formulation production, the suitable cleaning treatment needs to be set up to guarantee removing of any residue with the earlier products.

9. When developing a document, evaluate the context where the document may very well be utilized Down the road and whether or not the reader has adequate qualifications information.

This can be performed employing Laptop or computer-primarily based details or manual solutions. Retrospective Validation is completed when:

Transient description of ventilation systems. Extra information ought to be offered for significant places with probable danger of airborne contamination (schematic drawing of systems). Classification with the rooms utilized for the manufacture of sterile products should be stated.

This text explores key variances involving high quality assurance and good quality Command in the pharmaceutical industry. It explores their definitions, roles, and importance in ensuring regulatory compliance and item top quality. Additionally, it examines how these tactics influence drug and healthcare more info machine advancement, producing processes, and General high-quality management systems in pharmaceutical organisations.

The apply of validating documentation that demonstrates a course of action will constantly result in a product that meets anticipations is recognized as validation. Validation experiments, according to GMP, are A vital ingredient of GMP; they must be completed in accordance with predetermined protocols. System, testing, and cleaning are definitely the bare minimal that must be validated if you want to establish Regulate procedures that watch output and validate producing procedures Which may be causing variability in drug items. One of several essential parts in getting and preserving the ultimate products's top quality is validation. The accuracy, sensitivity, specificity, and repeatability with the check techniques utilized by the companies are supplied by the validation analysis, which have to be recognized and recorded.

Validation could be the artwork of creating and practising the designed methods together with Along with the documentation. Course of action validation emphasize on procedure designelements and retaining approach Command through commercialization andcommunicate that process validation is undoubtedly an ongoing method and alignprocess validation routines with product lifecycle. System click here validation alsoemphasizes the function of objective steps and statistical resources & analysesand emphasizes awareness, detection, and Charge of variability and givesassurance on consistent of excellent/productiveness all through everyday living cycle of solution.

The very first batch shall be dispatched after the completion on the third batch of manufacturing, screening, and assessment of success.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Shane West Then & Now!

Shane West Then & Now! Kane Then & Now!

Kane Then & Now! Barbara Eden Then & Now!

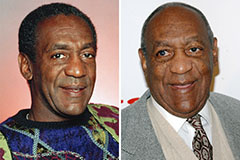

Barbara Eden Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!